Use this text to share information about your brand with your customers. Describe a product, share announcements, or welcome customers to your store.

Use this text to share information about your brand with your customers. Describe a product, share announcements, or welcome customers to your store.

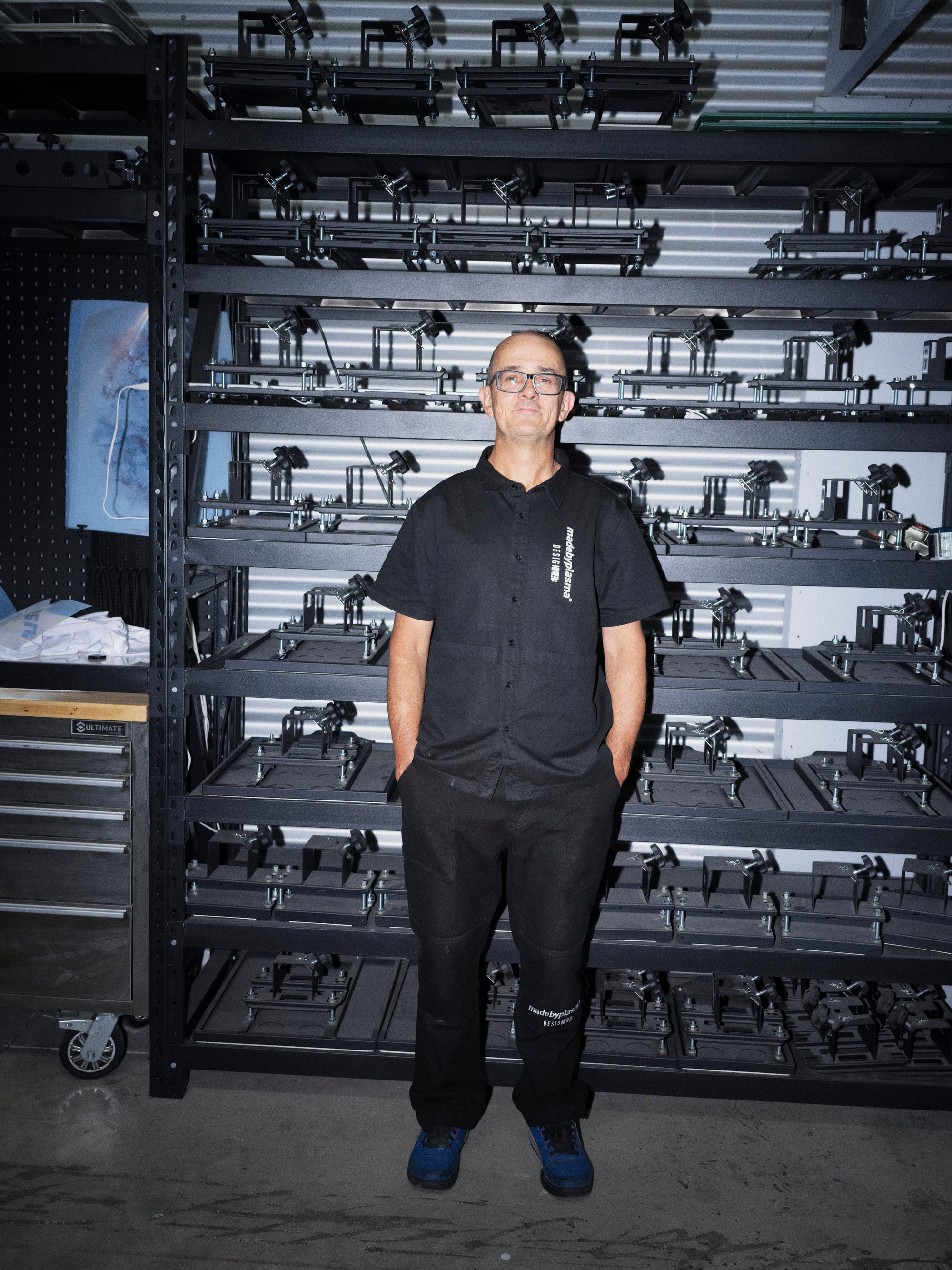

Create and supply your order in ten days. that's madebyplasma.

Our state-of-the-art automatic equipment and streamlined in-house production process ensure that we deliver locally made merchandise to you on time and in full at globally competitive prices.

What We Do?

Step by step process on how to create and supply your custom merchandise.

OUR TECHNIQUES

We are an apparel research lab dedicated to the art and science of screenprinting and apparel decoration.

made to order and made to last.

Below are the techniques and applications we use daily. If you require anything else, get in touch. thats madebyplasma.

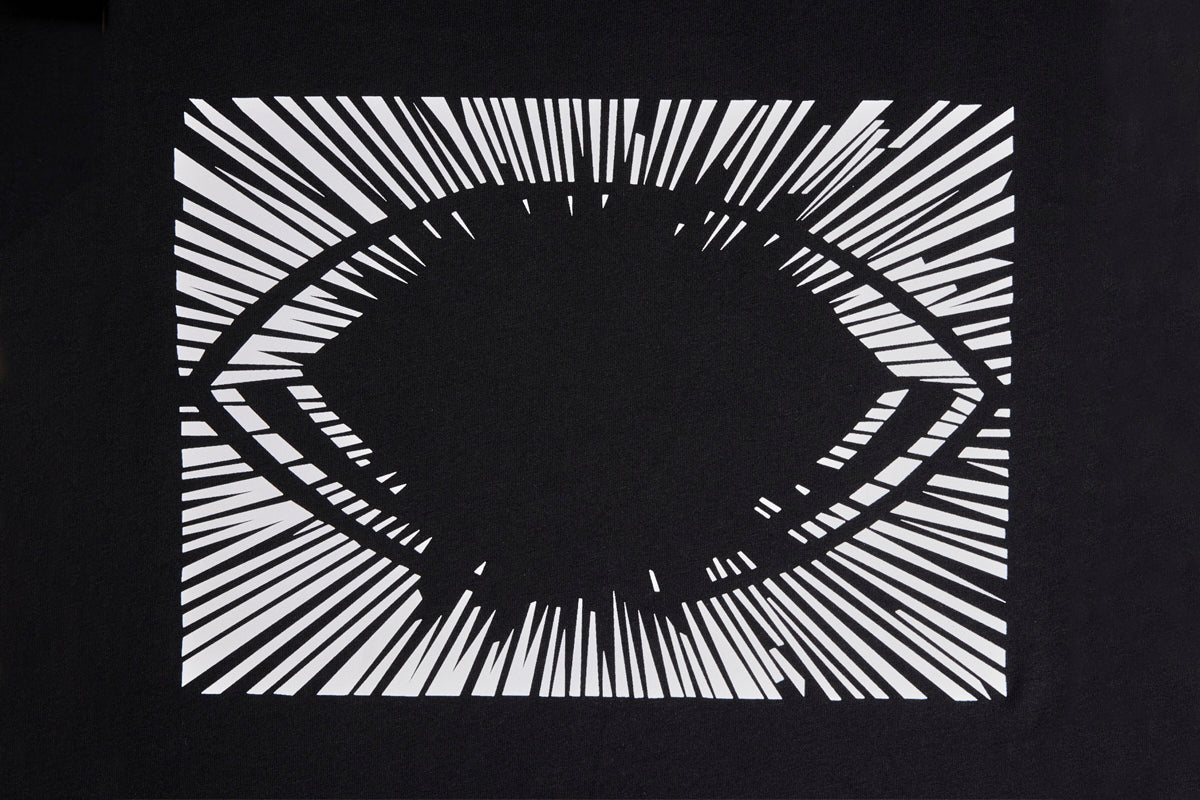

BASE + WHITE INK

A white base in screenprinting acts as a crucial layer on dark fabrics, providing an opaque foundation that enhances the vibrancy and accuracy of top colours. It ensures the fabric's original colour doesn't interfere with the design, delivering a clear, bold, and true-to-design result. Without a base, especially on darker fabrics, colours may appear dull or distorted, compromising the intended look of the print.

BASE VS NO BASE

Screenprinting with a base involves applying white, grey or, at times, black before adding top colours, providing vibrant prints on dark garments. No base means printing directly on the garment, usually lighter fabrics for a softer, more breathable feel. Printing with no base on darker garments will affect the intended print colour, as it will not be opaque enough to completely block out the garment's colour.

BASE + WHITE WATERBASED INK

Base + water-based screenprinting applies a white underbase on dark or coloured fabrics before adding top-colored inks. This process ensures vibrant, opaque colours and allows intricate designs to stand out. Water-based inks maintain the fabric's softness and breathability, providing comfort while achieving bright, detailed prints. It’s ideal for creating high-quality, bold designs without compromising the feel of the garment.

BLACK ON BLACK TONAL

Screenprinting black ink on black garments creates a subtle, contrasting look using gloss or matte ink to make the design stand out while keeping a monochromatic style. Similarly, white ink on white garments produces a sleek, tone-on-tone effect. This is one of madebyplasma’s specialties, offering unique, refined designs that enhance the garment's style without overwhelming it.

HALFTONE GRADIENT

Halftone gradient screenprinting simulates continuous-tone images by using tiny dots of varying sizes and spacing. By adjusting the dot density, this technique creates smooth transitions from light to dark, perfect for reproducing intricate gradients and photographic effects. It’s ideal for detailed designs and adds depth to prints. madebyplasma specialises in this method of technical printing.

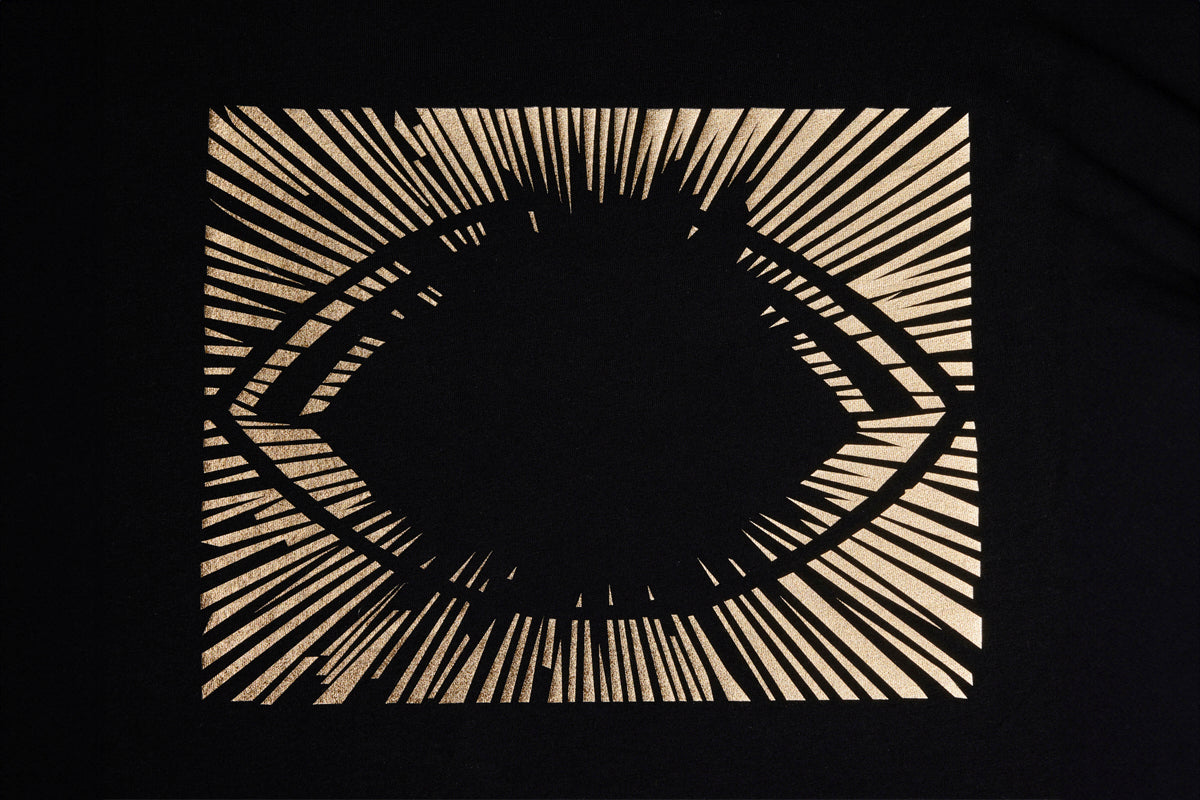

METALLIC INK

Screenprinting with metallic ink uses metallic pigments to produce a shimmering, reflective finish that adds a bold, eye-catching effect to designs. This technique enhances logos, text, or artwork with a distinctive high-gloss, metallic appearance, making it perfect for adding a standout element to garments. Metallic screenprinting is ideal for achieving a striking visual impact on apparel.

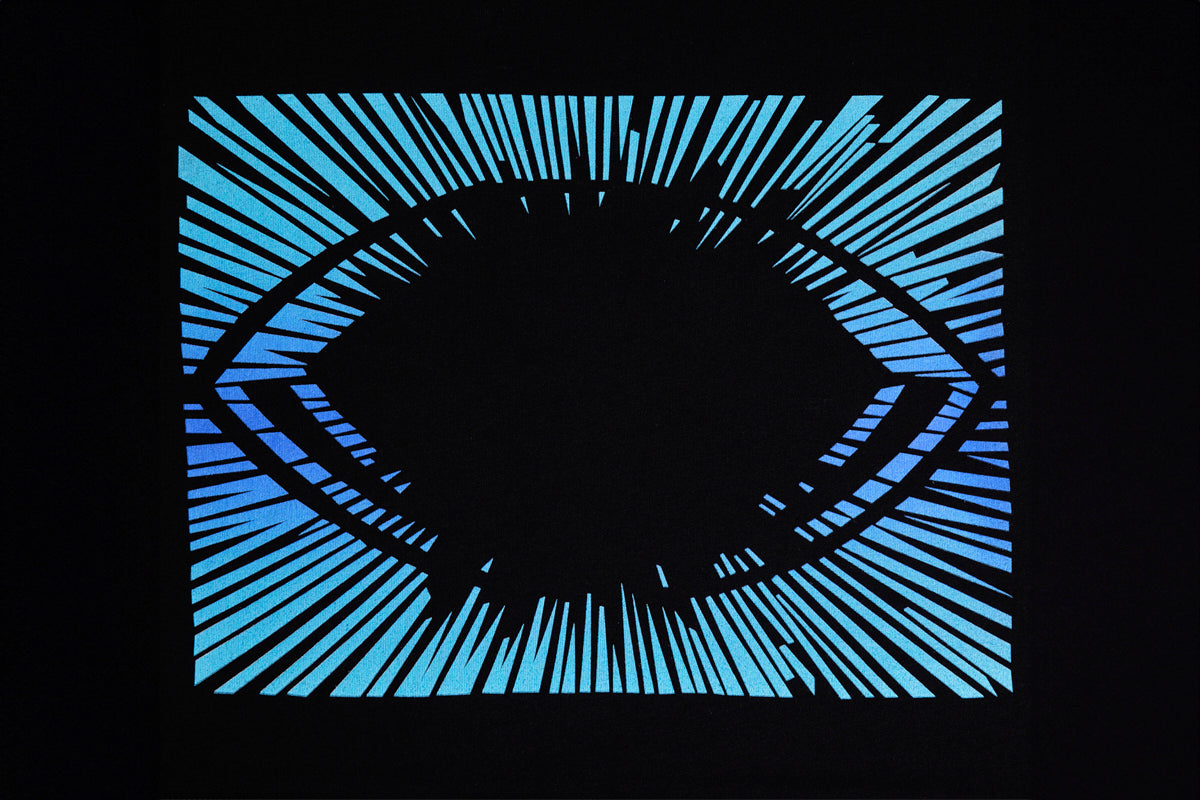

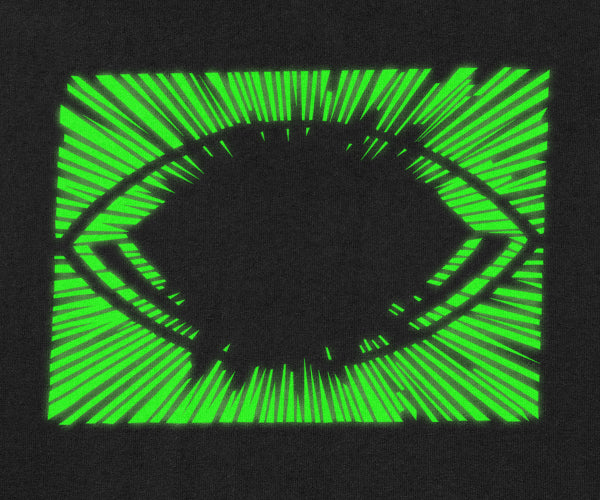

GLOW-IN-THE-DARK

Glow-in-the-dark screenprinting uses phosphorescent ink that absorbs light and glows in the dark, creating eye-catching luminescent designs. This technique adds a fun and unique element to garments, making them stand out in low-light environments. It can be combined with standard inks for an added effect, making it perfect for events, nightlife, or novelty apparel.

SIMULATED PROCESS

Simulated printing in screenprinting uses halftone dots and a limited number of ink colors to recreate full-colour, photorealistic images. By blending various ink hues, this technique simulates a wide color range, resulting in detailed, vibrant, and complex designs. It’s ideal for printing high-quality, intricate artwork on garments, especially on dark fabrics, while minimising ink usage.

CMYK

CMYK screenprinting, or four-colour process printing, reproduces full-colour images. It utilizes four ink colours, Cyan, Magenta, Yellow, and Black, which are layered and blended to create a wide range of colours. Each colour is printed on a separate screen, allowing for detailed and complex designs, such as photographs and multi-coloured graphics, to be accurately reproduced onto the garment. This method is ideal for achieving high-quality, vibrant prints on t-shirts, with intricate details and subtle colour variations, another madebyplasma speciality.

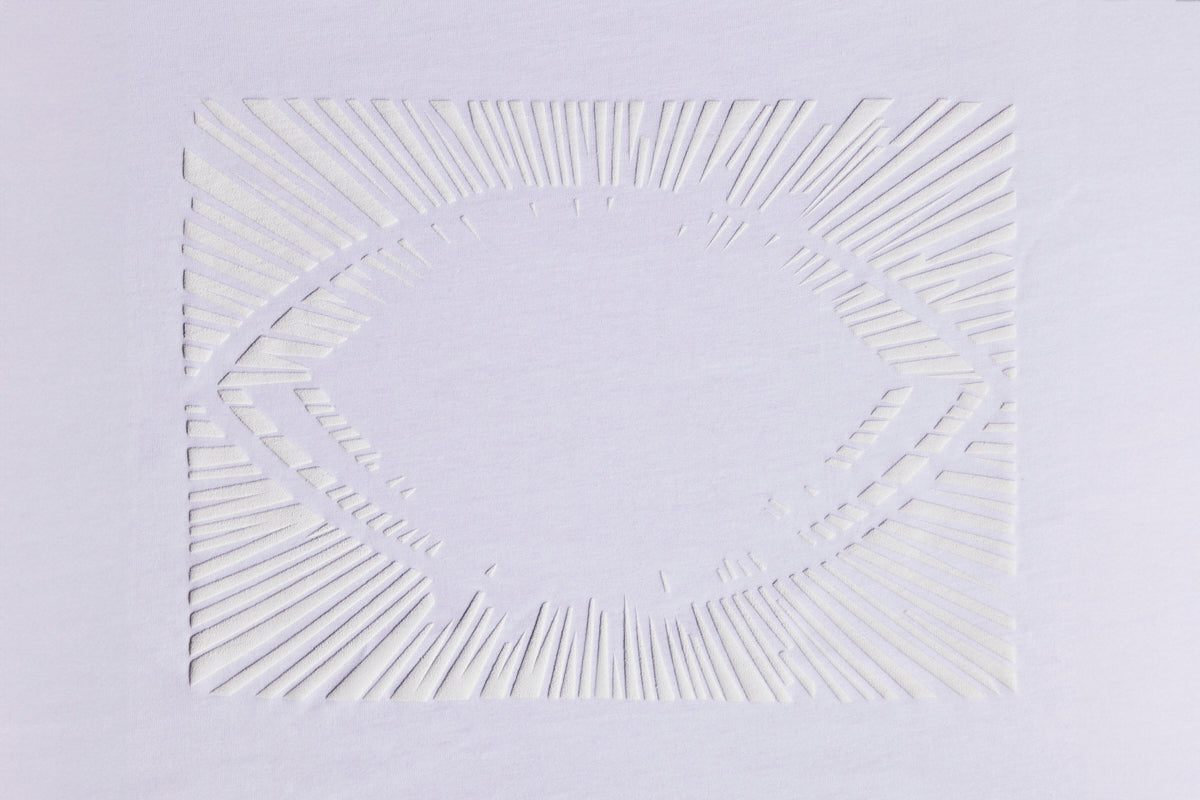

PUFF PRINT

Screenprinting with puff ink involves using a special ink and activating agent that expands and rises when cured through the oven, creating a raised textured effect. This technique adds dimension and a tactile feel to the garment.

HIGH DENSITY

High-density screenprinting is a technique that uses a thick, raised ink application to create a 3D or textured effect, enhancing the design's tactile and visual appeal. It's ideal for adding depth and impact to the graphics.

METALLIC INK

Screenprinting with metallic ink uses metallic pigments, creating a shimmering and reflective finish

NEON INK

Neon inks are bright and vivid, adding bold and eye-catching design elements. It works best on light-coloured garments.

WHITE ON WHITE TONAL

Screenprinting white ink on white garments achieves a contrasting look. A gloss or matte ink makes the design visible while maintaining a monochromatic style; similarly, Blank ink on black garments will achieve similar results. Another madebyplasma speciality.

WHITE ON WHITE PUFF PRINT

Screenprinting white puff ink on white garments achieves a contrasting and tactile look and feel. Puff ink is general matte in nature and makes the design visible while maintaining a subtle monochromatic style; similarly, Blank puff ink on black garments will achieve similar results. Another madebyplasma speciality.

PRINT + EMBROIDERY

Combining screeprinting and embroidery in a design involves using both techniques to create a visually appealing and textured effect. Screenprinting adds vibrant colours and details to the design, while embroidery adds a tactile and three-dimensional element.

EMBROIDERY SATIN STITCH

Embroidering with a satin stitch involves closely spaced, parallel stitches that create a smooth and shiny surface. This technique adds a visual appeal for that high-quality look.

EMBROIDERY - TATAMI STITCH

Embroidering with tatami stitch for apparel utilises closely spaced horizontal stitches to cover larger areas. This technique creates a smooth, textured, woven appearance, enhancing designs on clothing with a unique and visually appealing pattern for both aesthetic and function.

EMBROIDERY - RUNNING STITCH

A running stitch is a simple, continuous line of short stitches. This technique creates delicate and refined outlines and details in designs, offering a clean and subtle appearance.

EMBROIDERY - METALLIC THREAD

Embroidering with metallic threads involves using specialised threads with metallic fibres, such as gold or silver.

WHITE HEAT TRANSFER - VINYL

Heat transfer vinyl (HTV) for apparel is a versatile material that adheres to the fabric when a heat press applies heat. It allows for custom designs, logos, and graphics, offering endless creative personalisation and branding possibilities. Its applications span from t-shirts to sportswear and waterproof gear.

HEAT TRANSFER - FLOCKING

Heat transfer flocking adds a velvety texture to the garment. This technique creates a tactile effect with a soft, plush feel that adds an elevated dimension to the graphic.

HEAT TRANSFER - 3M REFLECTIVE

Heat transfer 3M reflective material that illuminates when exposed to light. This technique creates visibility-enhancing designs on clothing, ideal for safety gear, sportswear, and outerwear.

WATER-BASED DISCHARGE

Discharge printing is a technique that removes the colour from dyed fabric, leaving a soft, breathable print with no added texture. It's ideal for achieving a vintage or faded look.

SCREENPRINTED NECK LABELS

Internal neck prints offer custom designs and information printed inside a garment's neckline, providing branding and personalisation. By removing the original labels, the garments immediately become yours and elevate's your brand.

NECK WOVEN LABELS

Internal custom woven neck tags add a personalised touch to garments, featuring your brand logos and messaging. Removing original labels enhances brand identity and recognition of your label. Ideal for streetwear and fashion brands.

HEM & CUFF WOVEN LABELS

Add a video popup link to show a play button. Share blog posts, products, or promotions with your customers. Use this text to describe products, share details on availability and style, or as a space to display recent reviews or FAQs.

DIRECT TO FILM - DTF

DTF printing transfers designs onto garments by printing on film with an inkjet printer using water-based inks. A powdered adhesive is applied to the film, melted, and bonded to the design with heat. The film is then pressed onto the fabric, transferring the design. DTF printing offers vibrant colours, intricate details, and excellent durability, and works on various fabrics, including cotton, polyester, and blends. It is ideal for custom apparel, especially for smaller orders requiring high colour and detail.

BLACK WATERBASE INK ON WHITE

Waterbase Ink colours work perfect for a nice hand-feel on lighter garments. Also an eco-friendly alternative to plastisol inks.